3A molecular sieve is an alkali metal alumino-silicate with a pore opening of approximately 3 angstroms.it has advantages in crush strength durability and high rate of adsorption, it can remove moisture in both liquid and gas applications. Type 3A molecular sieve used in general Moisture Removal of the ethanol, natural gas, hydrocarbon liquids, Refrigerant Drying, Desiccant Dryer, Drying of LNG/LPG/CNG,cracked gas dehydration, and refrigerant dehydration.

1. BOAO 3A molecular sieve Synonym: 3A EDG; Z3-03; Siliporite® EPX 3B and Siliporite® EHP; SYLOBEAD® molecular sieves.

2. Typical Chemical Formula: 0.4K2O.0.6Na2O.Al2O3.2.OSiO2.4,5H2O

3. CAS NO.: 1318-02-1

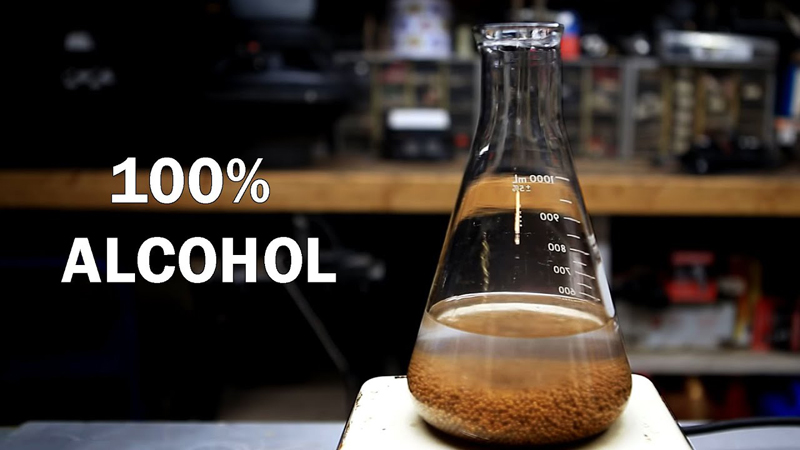

Ethanol dehydration typically occurs in a PSA unit. Water is adsorbed into the molecular sieve from the ethanol-water feed.Dehydration of ethanol in azeotropic conditions (93-96 % v/v) using the Pressure Swing Adsorption (PSA) process with molecular sieves columns offers significant economic and environmental advantages.BOAO 3A Molecular sieve used to dehydrate ethanol should have the following characteristics:

• Mechanical integrity to withstand demands of pressure swings with minimal breakage or dust generation

• Adsorption effciency and selectivity to allow for rapid removal of water with minimal ethanol co-adsorption.

Technical Specifications

Item | Unit | 3A Bead | 3A Pellet |

Diameter | mm | 1.6-2.5 | 3.0-5.0 | 1/16″ | 1/8″ |

Static H₂O Adsorption | %wt | ≥21.5 | ≥21.5 | ≥21.5 | ≥21.5 |

Bulk Density | g/ml | ≥0.70 | ≥0.70 | ≥0.70 | ≥0.70 |

Crush Strength | N | ≥35 | ≥80 | ≥40 | ≥80 |

Loss on Attrition | %wt | ≤0.1%wt | ≤0.1%wt | ≤0.25%wt | ≤0.25 |

Package Moisture | %wt | ≤1.5%wt | ≤1.5%wt | ≤1.5%wt | ≤1.5%wt |

Note: based on internal manufacturing’s testing.

Zeolite Molecular Sieve 3A Storage & Regeneration

•Storage

Because of its high and fast adsorption capacity, molecular sieve 3A should not be left exposed to open air and should be stored in dry conditions with air-proof packaging. This product should not be exposed to temperatures exceeding 230˚C (450˚F).

•Regeneration

Molecular sieve 3A can be regenerated or activated either thermal regeneration method(Thermal Swing Adsorption, TSA); To remove moisture from a 3A molecular sieve, a temperature of 200-230°C (390-570°F)is required. Molecular sieve 3A can also be regnerated or activated by lowering the pressure in the case of pressure swing processes (PSA). A properly regenerated or activated molecular sieve can give moisture dew points below -100°C. The outlet concentrations on a pressure swing process will depend on the gas present, and on the conditions of the process.